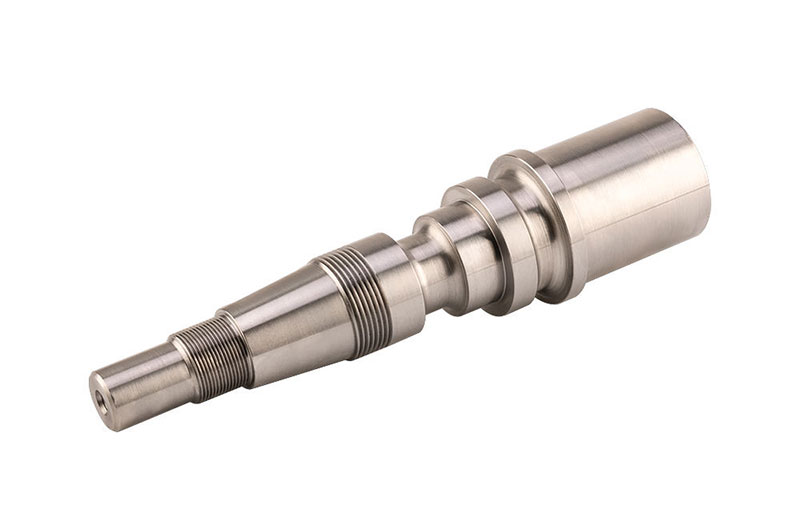

What is a Machined Shaft?

A machined shaft is a cylindrical or round mechanical part that transfers rotational motion and power between various machine components. Depending on the intended application’s requirements, these machined shafts are often made of metals like aluminum, titanium, steel, or stainless steel. These shaft parts are important in transmitting rotational force and torque within machinery, facilitating …