Electronics manufacturers leverage the precision, adaptability, and repeatability of CNC machining technology required in competitive markets to create different machined electronic products and components, including:

Printed Circuit Boards (PCBs)

Printed circuit boards are vital components of almost every electronic product because they are a point of connection for various components. They often include conductive tracks made from copper and a non-conductive base layer below.

High-precision CNC machining for PCBs facilitates the creation of intricate pathways and cutouts, ensuring complex circuits fit into smaller spaces. Moreover, the ability of multi-axis CNC machines to cut different materials like copper-clad laminates, fiberglass, and other advanced composites allows manufacturers to meet various electronic applications’ specific thermal and electrical properties.

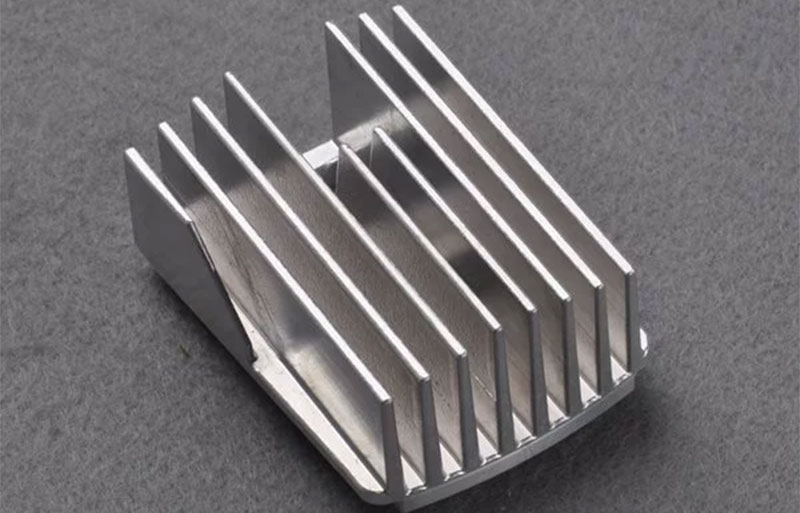

Heat Sinks

Heat sinks are another popular electronic device component acting as a passive heat exchanger. They dissipate generated heat into air or liquid coolant and mitigate overheating to ensure proper functioning. CNC precision machining allows manufacturers to meet the specific design requirements of electronic heat sinks since they often vary in size.

In addition, micro CNC machines can handle miniature electrical components, unusual fin patterns, and other heat sink design features for an electronics prototype and low-volume productions.

Semiconductors

Semiconductors have contributed to technological breakthroughs across various industries, especially electronics and aerospace. A semiconductor is an electrical component that functions as a vacuum tube a hundred times its size. It includes heat sinks, wafer carriers, and precision housings. CNC machining of electronic components such as semiconductors ensures high precision and quality for properly functioning these components.

CNC technology provides the accuracy and material compatibility required to make semiconductor components. Moreover, smaller, more precise package designs are the demand of the increasingly competitive semiconductor market. These components often require tight tolerances and specific surface roughness, which CNC machining delivers.

Consumer Electronics

Consumer electronics are amongst the various CNC machined electronic parts, ranging from sturdy bases of laptops to sleek frames of smartphones and gaming accessories.

In addition, precision CNC machining offers aesthetic appeal and precise casings for small, intricate components of wearable devices like fitness trackers and smartwatches. Gaming accessories like custom joystick housings and console parts are other common consumer electronics manufacturers create using CNC machining techniques.

Electronic Switches

All electronic devices have switches that control the current supply from small devices like mobile phones to big computer servers. CNC machining fabricates electronic switches with precise shapes and desired tolerance, ensuring they fit perfectly in an assembly. Following the rapid growth of the electronics industry, CNC machining allows the custom design of durable switches for sophisticated electronic devices, ensuring they function as required.

Casing and Enclosures

These electronic components are protective shells that ensure the proper functioning of electronic devices. With computer-controlled movement, electronic enclosure machining facilitates the fabrication of various types of casings and enclosures of different sizes and from preferred materials.

CNC machined enclosures and casings provide the functional protection and aesthetic appeal that guarantee the proper functioning and longevity of electronic devices like smartphones, digital cameras, and laptops.