The step turning process is fairly straightforward but requires patience. Generally, step turning starts with a uniform round stock mounted in the machine.

Then, an initial rough cut is taken to achieve a uniform diameter across the stock’s length and to remove any uneven features on the surface.

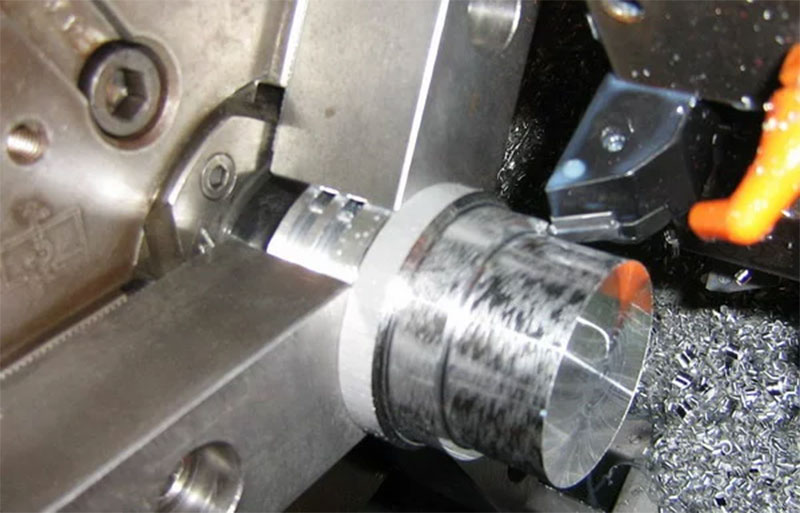

Afterward, machinists perform step turning in a gradual manner, decreasing the diameter of each section in multiple steps until they achieve the correct diameter. For each subsequent step, the cutting tool should ensure correct alignment and dimensions.

In the end, it is good practice to add a finishing cut. This helps achieve a fine surface finish and precise control over dimensions.