Have you ever wondered why the CNC machining cost for each project is different? The secret lies in the details that go into the CNC machining cost calculation. From raw materials to labor costs and machine time, several factors affect the price.

If you’re looking to calculate CNC machining cost, ensure you:

Factor in Material Costs

Your choice of CNC machining materials would directly affect the amount of raw materials you will get. To calculate the material cost, you need to multiply the volume of the material you need by its cost per unit.

For example, you may need up to 20 kg of aluminum to bulk produce multiple parts, and it costs $10 per kg. With no extra preparation cost, the material should cost $200 ($10 x 20 = 200)

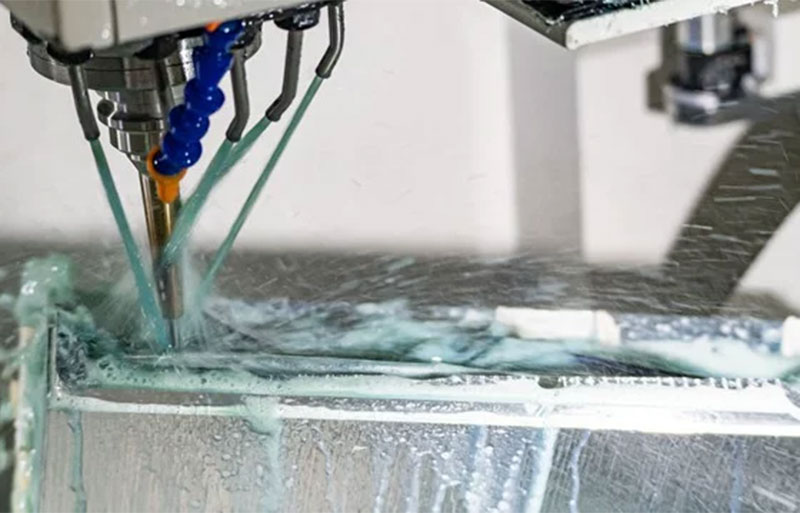

Determine the Machining Time

The amount of time you spend creating a part will definitely affect its price. You can, on your own, calculate the machine time by dividing the total length of the material by the machine’s cutting speed.

For instance, if the volume of material the machine will remove is 20 cubic inches and the average material removal rate is 0.5 cubic inches per minute, the total machining time for this process would be 40 minutes (20 cubic inches/ 0.5 cubic inches = 40).

Calculate the Machine’s Hourly Rate

Most CNC machines already come with a fixed hourly rate that factors in the type of machine, location, and the ease of operation. If the hourly rate for a machine is $100, you should have up to $300 to cover for 3 hours.

Include Labor and Setup Costs

Include the cost of hiring skilled labor to handle tasks like setup, programming, and production supervision. If you’re not sure, you can create an estimate based on the expected labor hours and the CNC machine shop’s hourly rate.

Account for Additional Expenses

Apart from the costs we’ve listed above, you should also prepare for additional expenses like surface treatment, tight tolerances, and other packages. Some special finishes may also lead to extra expenses.