Different Stages Of Tooling In Manufacturing

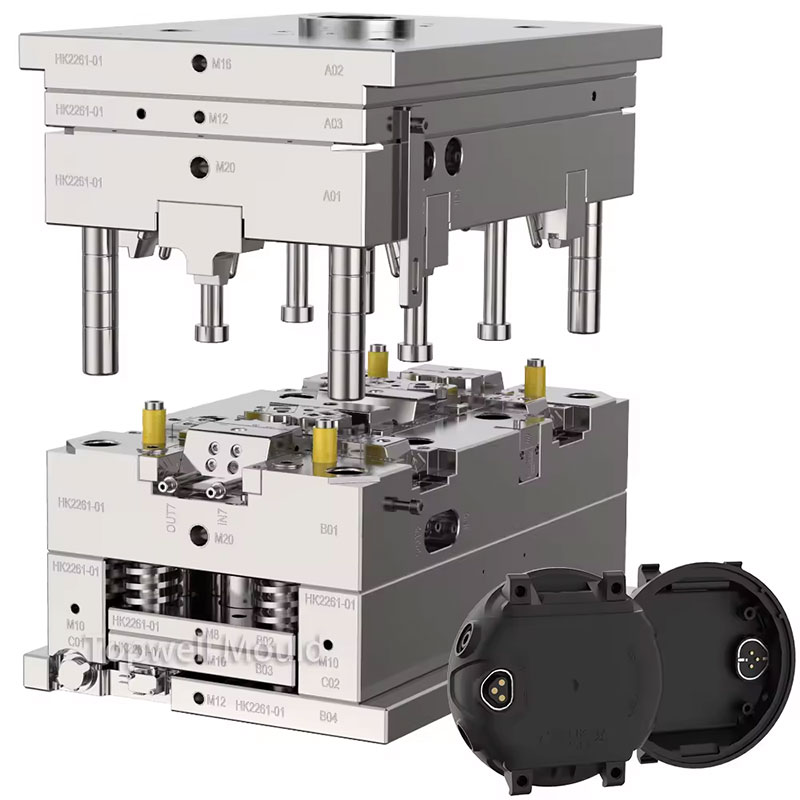

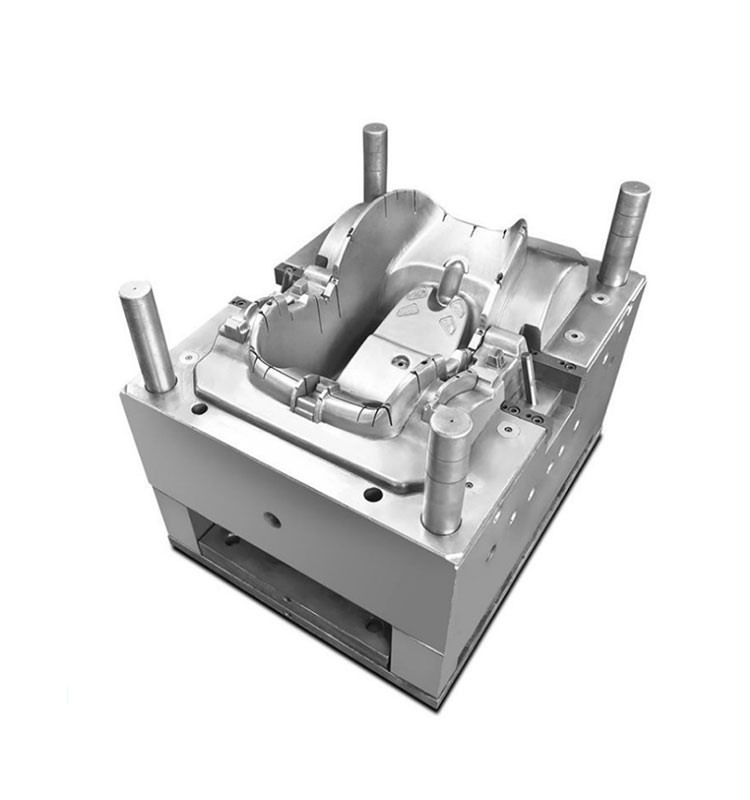

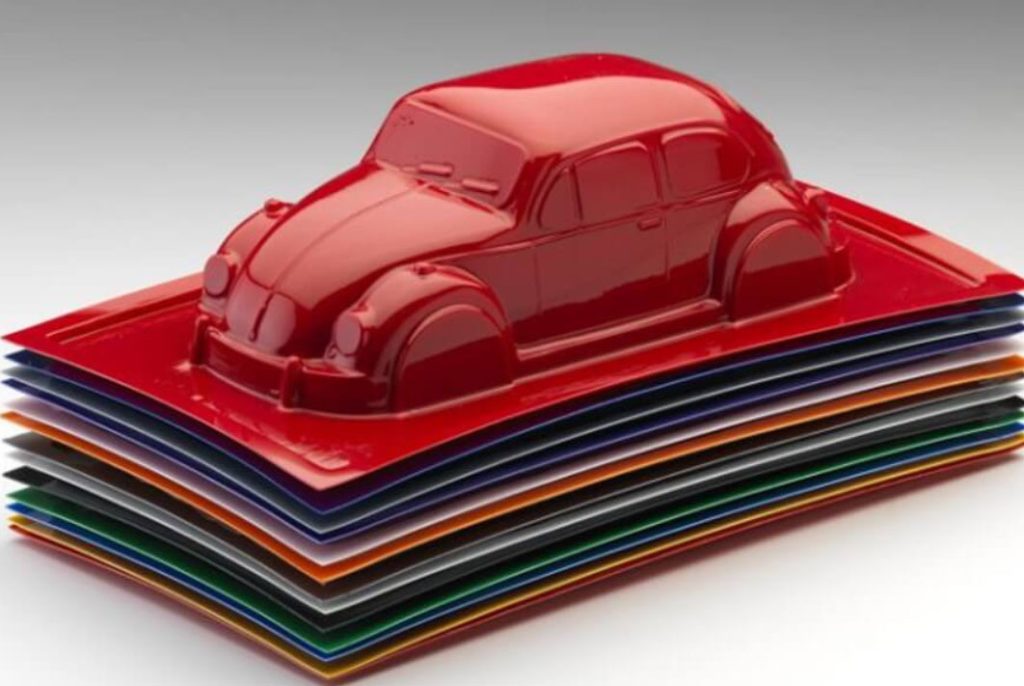

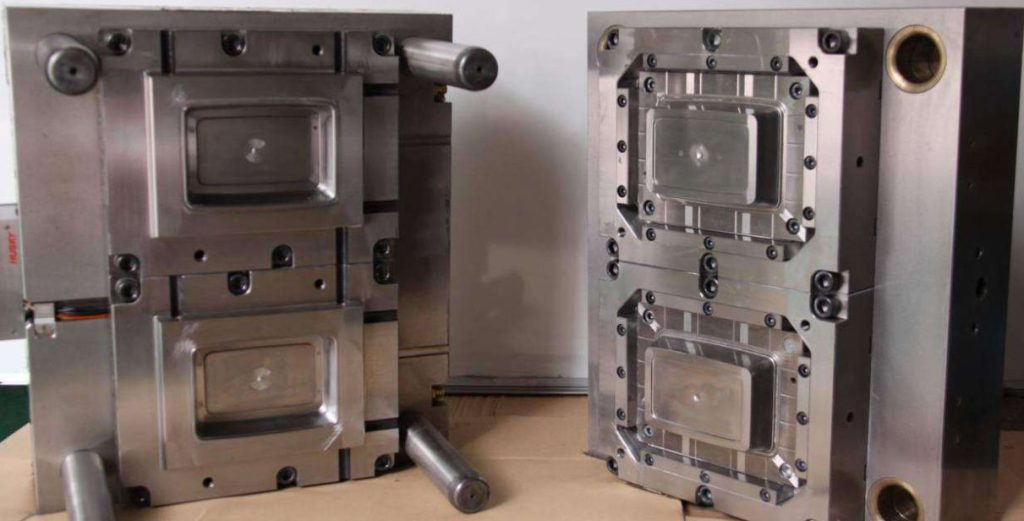

There are three main stages for tooling manufacture: prototype tooling, bridge tooling, and production tooling. Prototype ToolingThe first step in the tooling manufacturing process is prototype tooling. This entails making molds and tools to create prototypes or small batches of products. These are generally single-use tools that are crucial for testing and confirming the design …