Various turning operations are used in different manufacturing industries to create machine parts. This section will discuss the types of turning procedures used across various industries.

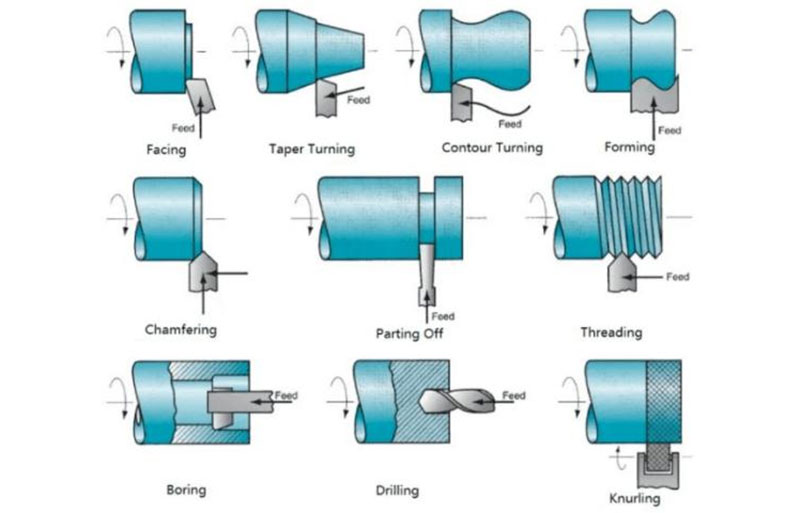

Lathing

It’s the most versatile operation involving excess material removal from the raw material’s outer surface. Lathing is done continuously until it achieves the perfect design. The operation gets the job done with great accuracy and finishing.

Boring

The process of removing material from a hole in a material. Boring machining comes in when a hole is already created. It is also used to correct a hole that is not perfectly round.

Tapping

The operation uses a tapping tool to create threads as they enter axially through the hole of raw material. The tap is a multipoint cutting tool, and the workpiece is made to rotate slowly while placed on a faceplate. Then, the fixture supports the tap on a tailstock spindle.

Knurling

Knurling helps to create a diamond-shaped pattern on the surface of the workpiece. It enhances the grip of the machine part, making it attractive. This operation is brought into contact with raw material, and the teeth are made to roll onto the workpiece.

Reaming

It is used to enlarge holes. The tool penetrates axially through the material to expand the existing hole to the diameter of the reamer. Reaming produces a rounder hole by removing a small amount of material, giving a better internal finish.

Parting

The tool makes a progressive cut across the workpiece, passing through the perpendicular axis as the workpiece rotates. As the operation continues, the cutting tool detaches and drops off the workpiece as it gets to the center.

Facing

This operation reduces the length of the workpiece, and facing inserts are the accurate size of a workpiece. The workpiece ends perpendicular to the axis of rotation. The tool moves along the workpiece radius to produce the desired length.

Grooving

The operation is also known as necking. It helps to create a narrow workpiece. The width of the cutting tool determines the size of the cut. This operation can create a narrow cut or remove material by moving radially.

Threading

The operation is a lathe machining process that uses mechanical tools to cut threads. The tool operates by moving along the side of the workpiece.

Drilling

It is usually the first step of operation used in creating internal features which will further require other operations for refining. Drilling is used to create a cylindrical hole in the workpiece of a material, usually metal.