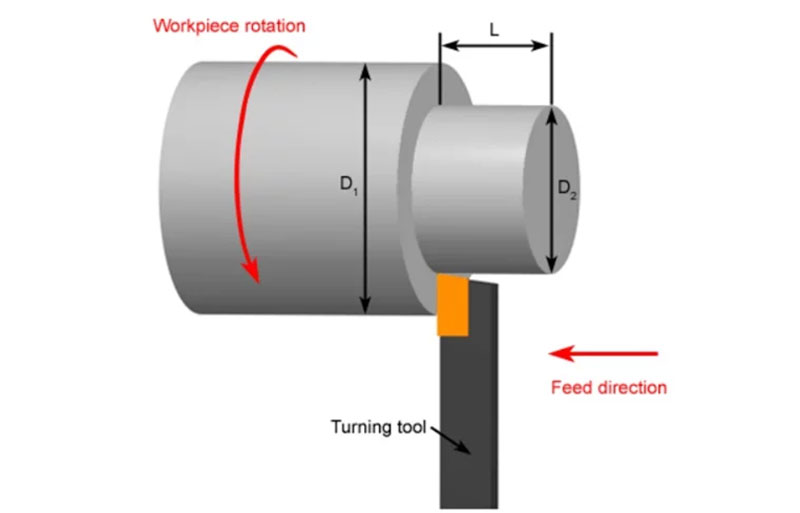

The step turning process is the more fundamental and simpler process in the step turning vs taper turning comparison. In step turning, a lathe machine is used to create multiple steps (sections with different diameters) along the length of the rotating cylindrical workpiece.

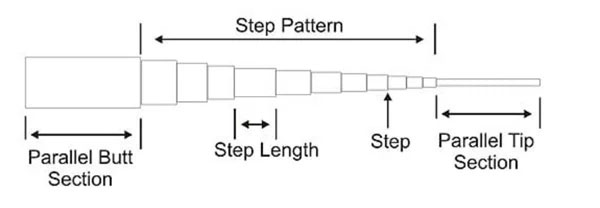

Each step is a section with a constant diameter. This indicates that the feed direction of the lathe-cutting tool is always parallel to the axis of the workpiece. Since the appearance of sections with different diameters resembles that of ‘steps’ as in a staircase, the name ‘step turning’ has become common. The figure below shows a typical multi-step shaft with the relevant terminologies.

The final workpiece may have any number of steps, depending on the design. These steps may have numerous applications like providing seats for mating components like sleeves, shoulders for locating bearings, or for aesthetic purposes.